Windows for sectional doors

Range of applictions

Windows are designed for installation in 40mm sectional door panels to ensure visibility and illumination of interiors by the daylight.

Construction of window

Two- component window frame is made of ABS by mould injection. This material is highly resistant to UV radiation, changes of temperature and it is scratch resistant. Glazing is made of 2 PMMA panes combined to Polyamide (PA6) spacer frame what ensures water resistance and thermal insulation similarly as in standard 2 pane windows. Due to hygroscopic properties of Polyamide PA6 possible humidity appearing between panes is absorbed by the spacer frame. The window is mounted to the panels by screws what makes windows ease to dismantle and reinstall in case of window of door panel failure.

Two types of windows are available: rectangular windows L2 and oval windows O2.

Plastic rectangular window L2

External dimensions: 635x332mm,

Internal dimensions: 545x242mm,

Installation opening dimensions: 605 x 302mm

Colours: Black (art. number); White (art. number)

Packaging: Cardboard box 8pcs (box dimensions: 65x35x45mm; weight: 18,4kg)

Pallet 96pcs (12boxes); dimensions: 120x80x150mm; weight: 220kg).

Design ensuring resistance to atmospheric conditions

Window installed in the garage door must be resistant to low and high temperatures, rain, strong winds and UV radiation.

We have applied several design solutions ensuring the highest quality of our windows:

Window frame is made of special material, called ABS, which is highly resistant to high temperatures and UV radiation.

Silicone sealing used on the external side of window guaranties tightness and water resistance.

Glazing consists of two panes made of 2mm PMMA combined with Polyamide PA6 spacer frame ensuring exceptional water resistance.

Internal window spacer frame is made of material with hygroscopic properties which absorbs humidity appearing between panes.

Screw fasteners for easy mounting and dismounting for repair, replacement or correcting improper installation.

Protection during transport and handling

To prevent scratching of panes surfaces they are covered with protective plastic foil which must be removed after completion of all construction and installation works. To remove the foil in a safe way, put little amount of alcohol on the corner of the foil, grab the rolled end of the foil and tear it form the pane surface.

Maintenance

Maintenance of PMMA glassing is very simple as it requires only flushing with a stream of water. Cleaning of glazing with traditional methods using aggressive detergents and rough brushes and cloths can scratch the surface of PMMA panes and shall not be subject to complaint procedures.

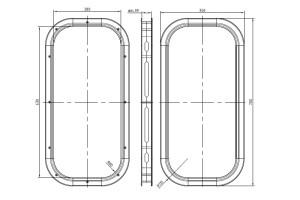

Plastic oval window O2

Oval window O2 for sectional doors:

External dimensions: 700x350mm,

Internal dimensions: 630x280mm,

Installation opening dimensions: 670x320mm,

Colours: Black, White

Packaging: Cardboard box 8pcs; Pallet 96pcs (12boxes);

Design ensuring resistance to atmospheric conditions

Window installed in the garage door must be resistant to low and high temperatures, rain, strong winds and UV radiation.

We have applied several design solutions ensuring the highest quality of our windows:

Window frame is made of special material, called ABS, which is highly resistant to high temperatures and UV radiation.

Silicone sealing used on the external side of window guaranties tightness and water resistance.

Glazing consists of two panes made of 2mm PMMA combined with Polyamide PA6 spacer frame ensuring exceptional water resistance.

Internal window spacer frame is made of material with hygroscopic properties which absorbs humidity appearing between panes.

Screw fasteners for easy mounting and dismounting for repair, replacement or correcting improper installation.

Protection during transport and handling

To prevent scratching of panes surfaces they are covered with protective plastic foil which must be removed after completion of all construction and installation works. To remove the foil in a safe way, put little amount of alcohol on the corner of the foil, grab the rolled end of the foil and tear it form the pane surface.

Maintenance

Maintenance of PMMA glassing is very simple as it requires only flushing with a stream of water. Cleaning of glazing with traditional methods using aggressive detergents and rough brushes and cloths can scratch the surface of PMMA panes and shall not be subject to complaint procedures.